Creating Quality Products

and Solutions

Since 1970

A&B Precision Metals, Inc., is a proud supporter of the ISO 9001:2015 Certified Quality Management System This system is testament to the experience and knowledge of each member of our Leadership Team, the commitment to quality displayed by each of our Employees, and complete confidence in our manufacturing processes. Certification in this Quality Management System is your assurance that any product we manufacture for your unique application will exceed both customer specifications and any related regulatory standards.

Our Services

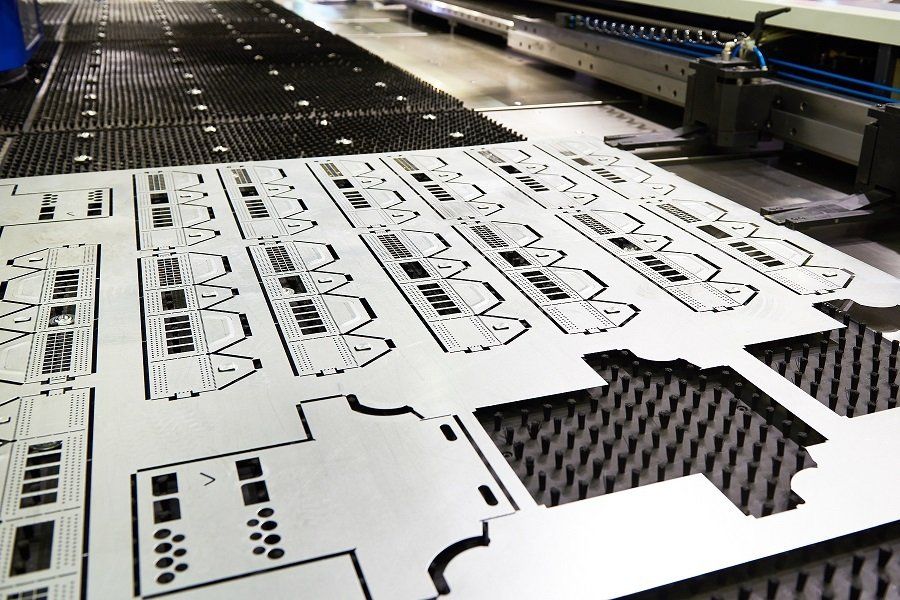

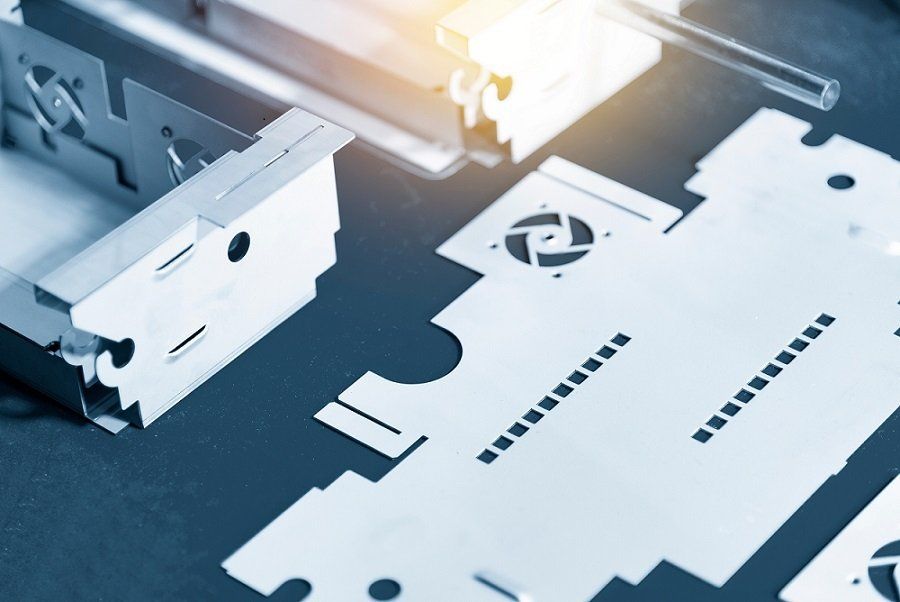

CNC Turret Punch & Laser

Our Profiling Team chooses the most advantageous manufacturing techniques for each individual situation. With modern state-of-the-art equipment, we maximize efficient quality output while maintaining rigid quality standards. Our 'lights-out' capabilities provide our customers with the flexibility of achieving prototype and high-volume production runs simultaneously.

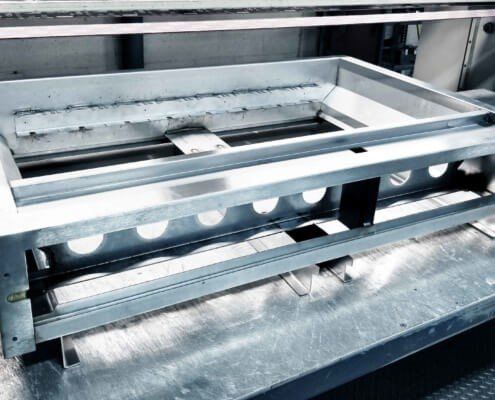

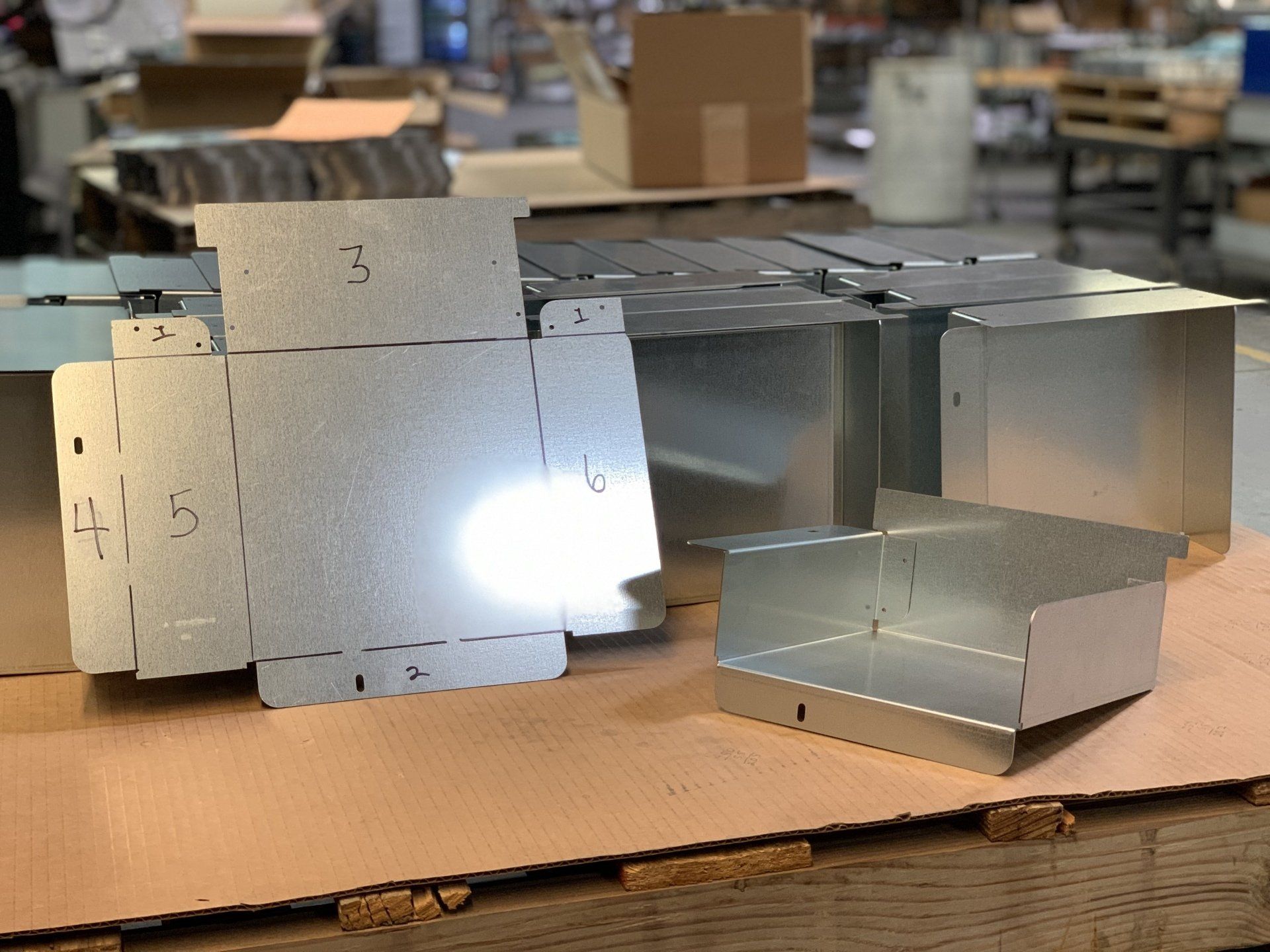

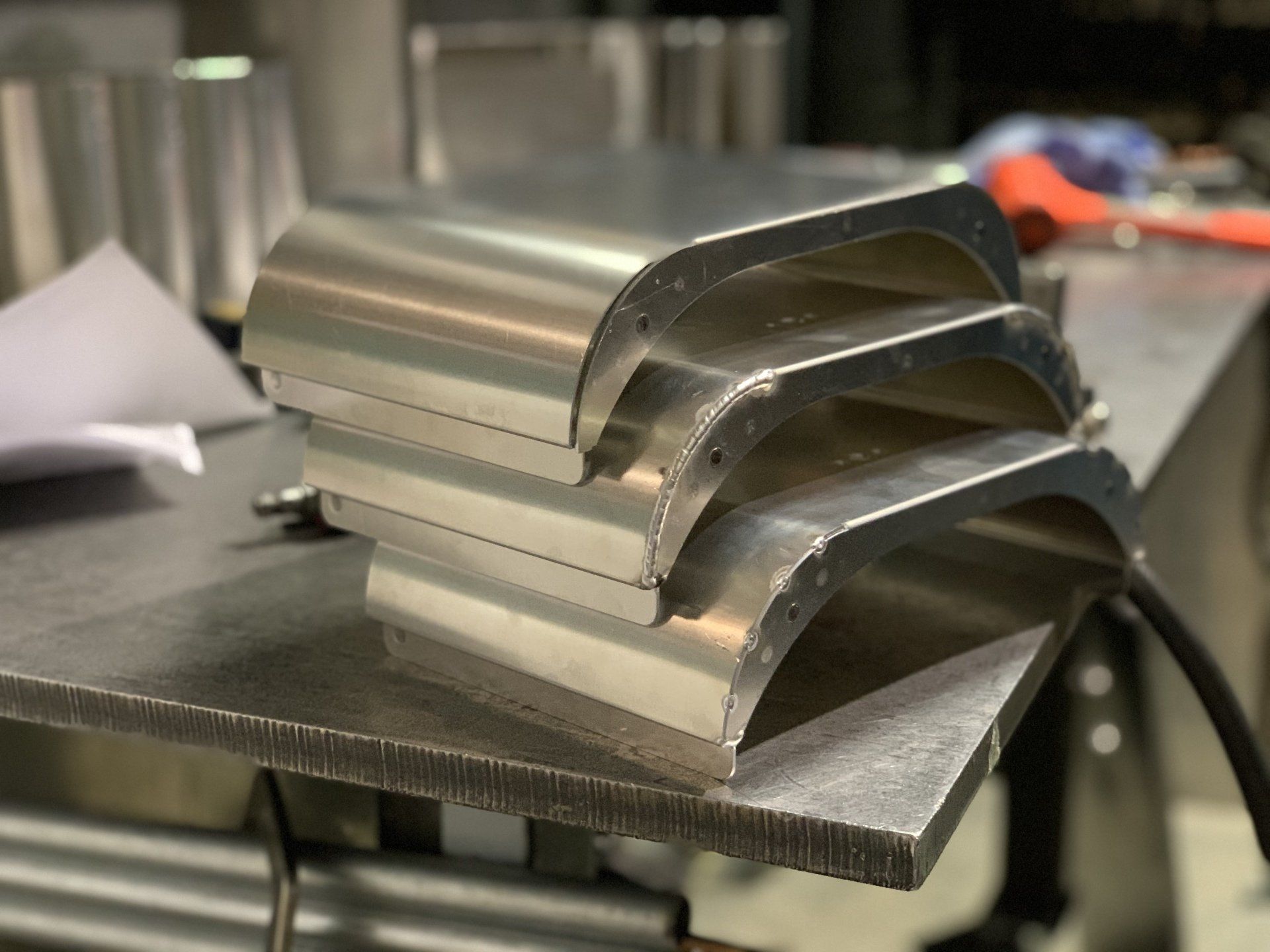

CNC Press Brake

Our Forming Team takes advantage of our Dual-Axis Press Brakes that shape components from very thin cosmetic materials up to 1/4 Inch thick material that is up to 10 feet long and contains multiple complex forms, angles, bends and assembly components. This is achieved while maintaining all esthetic requirements per customer specification.

Cosmetic Material Finishing

Our Finishing Team use many types of tools and specialized equipment to apply grains or other specified finishes to metal parts. This process also provides deburring functions which remove particles or sharp edges without causing dimensional changes to the parts. This extra cosmetic step ensures a high-quality, safe and functional product every time!

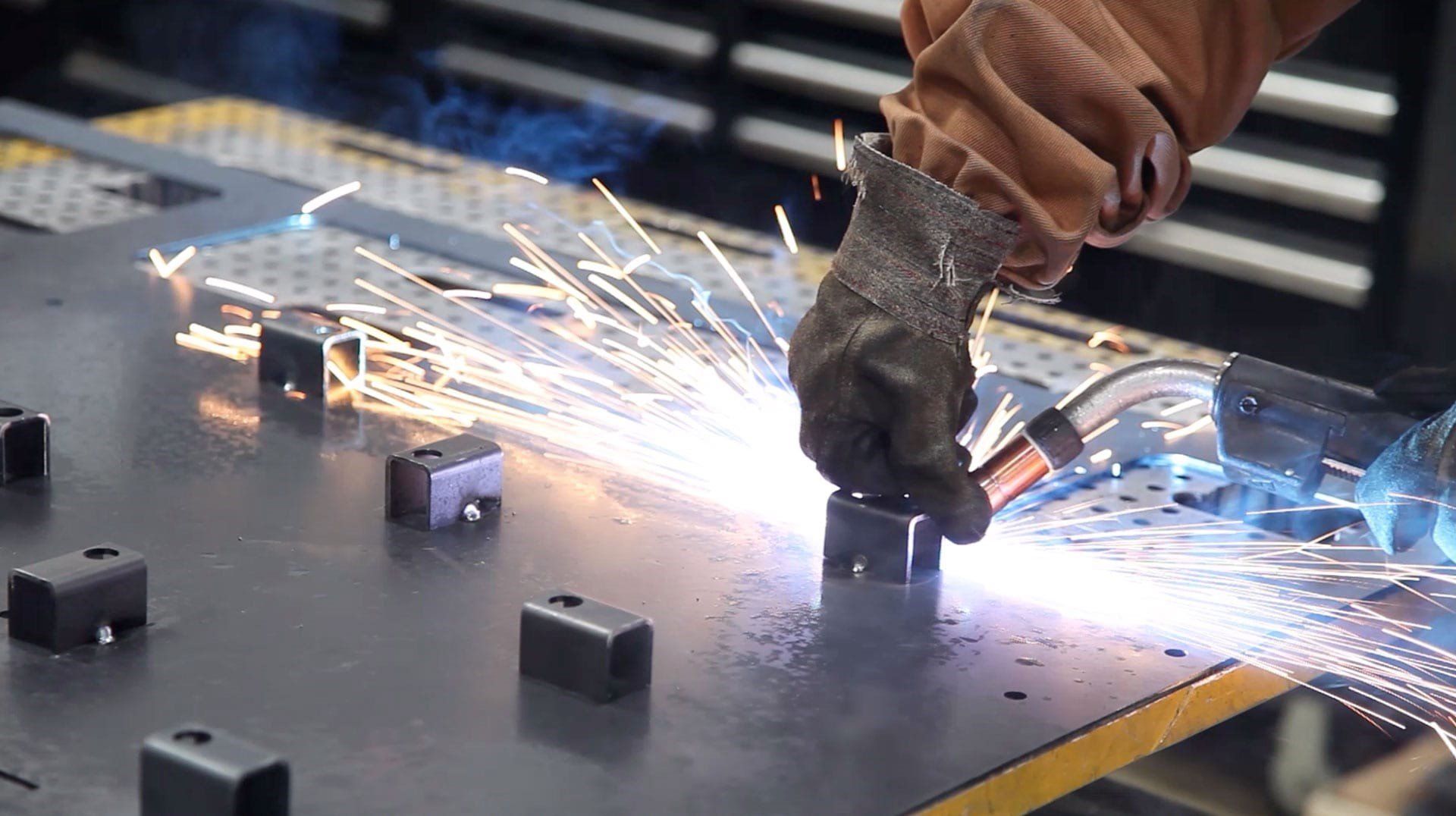

Specialized Welding

Our Welding Team utilizes both robotic and manual welding applications. Services include MIG and high cosmetic precise TIG welding functions in support of specialized customer needs. We are highly experienced in welding a variety of different metal types and thicknesses including aluminum, cold roll and hot roll, several varieties of zinc coated materials, and numerous classes of stainless steel.

Expert Spot Welding

Our Spot Welding Team provide significant production advantages to customers who require a high-speed assembly application with quick and accurate results. This function is utilized in both short-run or for larger production needs.

Quality Stud Welding Welding

Our Stud Welding Team has extensive experience with metals such as aluminum, stainless steel, galvanized steel and many others in order to provide high-quality resistance Stud application to customer designs.

Skillful Hardware Installation

Our Hardware Team use their talent and expertise to utilize our fully-hydraulic Haeger 824 hardware insertion machines to insert nearly every type and size of self-clinching fastener into all varieties of materials. Customer satisfaction is at the core of this application!

Superb Powder Coating

Our state-of-the-art Powder Coating System is 100% eco-friendly, provides 430 feet of conveyorized production line, a 10-stage multi-metal pretreatment system, 2 coat in-line capabilities, and utilizes 6 Automatic and 4 Manual quick color change applicators. We take great pride in the product we manufacture, and when that product travels through and exits the powder coat line, we are proud of the results! We're sure you will be highly pleased as well.

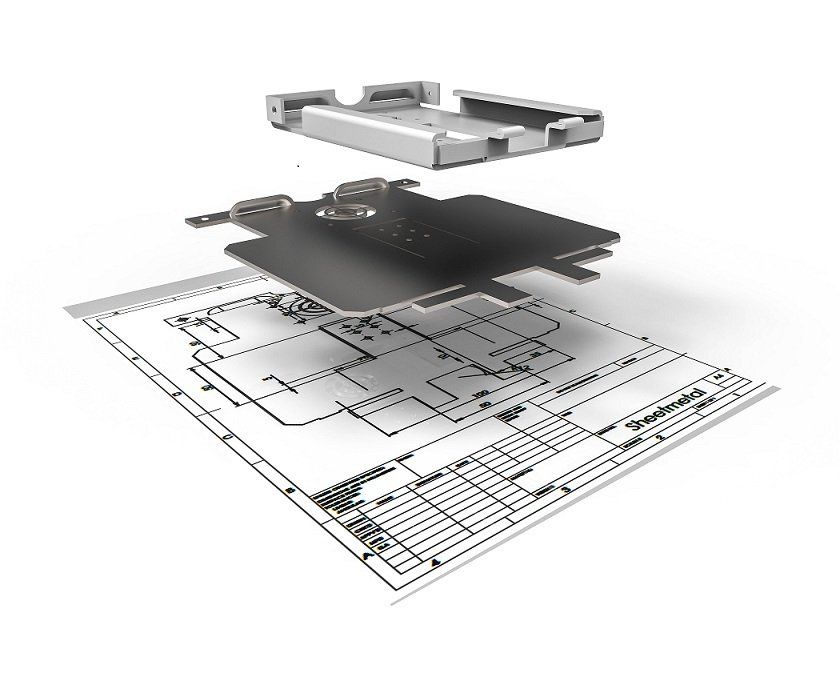

Knowledgeable Design Support

Our Design Support Team are able to assist with creating, updating, revising, and refining numerous SolidWorks 3D models and associated 2D drawings. From simple to complex concepts, quality and technical expertise assure a seamless transformation of ideas into reality. Uncomplicated and effortless methods of data transfer for existing or new product ideas is at your fingertips. Our Design Support Team is here to meet your customer specifications and needs.

Artful Assemblymbly

Our Assembly Team use a variety of hand and power tools following industry standards, appropriate assembly methods, and well-established quality procedures to complete simple to complex mechanical fabrication of your components and products. This team also is responsible for the final finishing, packaging and preparation of your items for shipment.

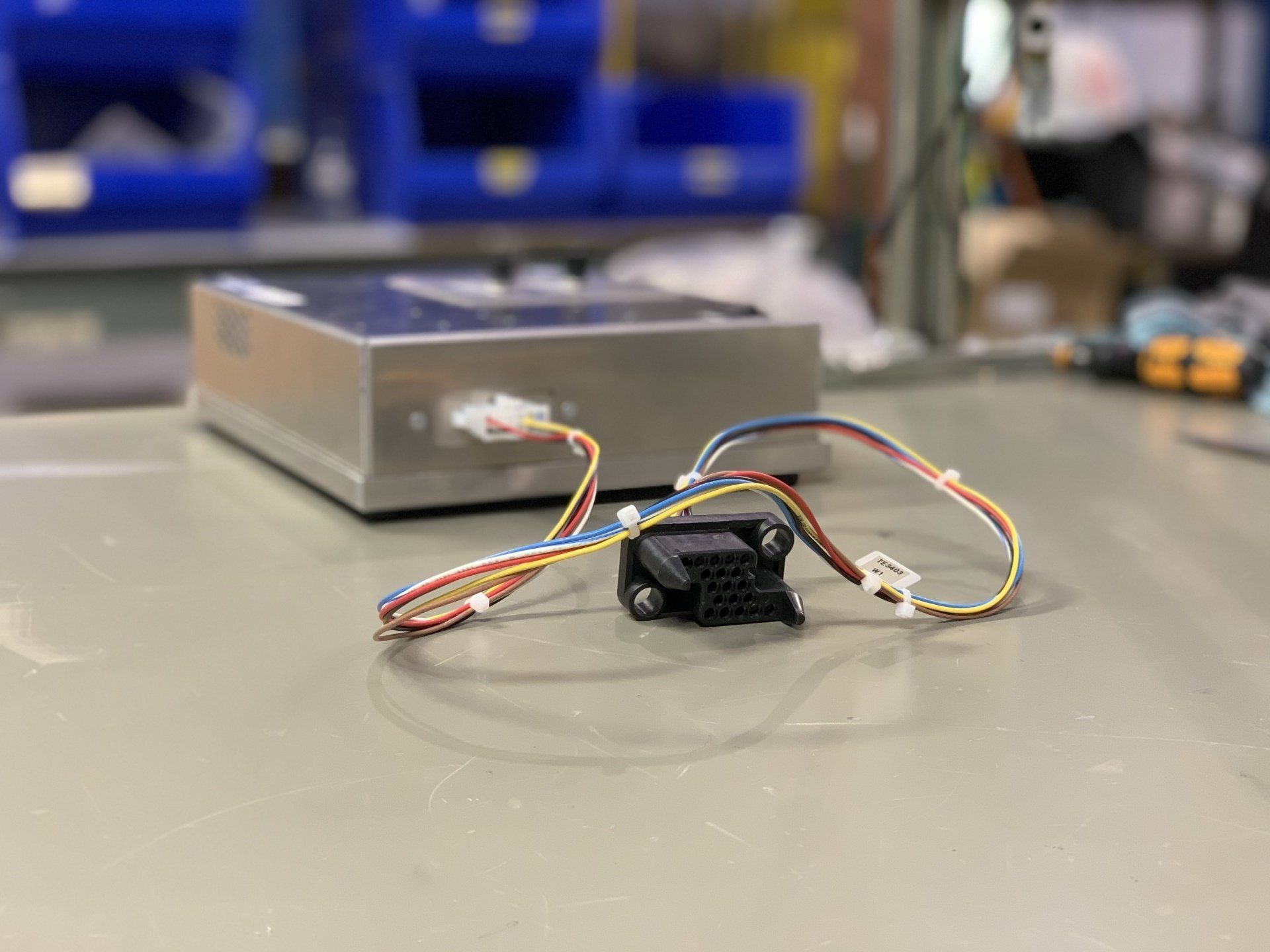

Safe Electrostatic Discharge

Our Trained and Certified Technicians analyze and troubleshoot electrical problems and conduct diagnostic repair. This process includes dis-assembly, electrical adjustment or wiring replacement, circuit board verification, other electrical component certification, and re-assembly - all in a safe and grounded environment.

Restoration & Refurbishing

Our Refurbishing Team are experts at dis-assemby and re-assemby of simple to complex components and parts. This process includes reconditioning, refurbishing, detailing and restoring to like-new condition your product to your specifications.